How Many Ounces In A Pound Of Freon

Arias News

Mar 20, 2025 · 5 min read

Table of Contents

How Many Ounces in a Pound of Freon? Understanding Refrigerant Weight and Measurement

The question, "How many ounces in a pound of Freon?" might seem simple, but understanding refrigerant weight and measurement goes beyond a straightforward conversion. This comprehensive guide delves into the intricacies of Freon (now more accurately referred to as refrigerants like R-134a, R-410A, etc.), its weight, and the importance of accurate measurement in HVAC systems. We'll explore the conversion, address common misconceptions, and highlight the safety considerations involved in handling refrigerants.

The Simple Answer: 16 Ounces in a Pound

Let's start with the basic conversion. There are 16 ounces (oz) in 1 pound (lb). This applies universally, regardless of the substance being measured, including Freon or any other refrigerant. This fundamental conversion is crucial for anyone working with refrigerants, whether it's for calculating refrigerant charge in an air conditioning unit or understanding the specifications of refrigerant cylinders.

Beyond the Basic Conversion: Understanding Refrigerant Properties

While the ounce-to-pound conversion is straightforward, the complexities arise when considering the properties of refrigerants themselves. Freon is a trade name, and modern refrigerants are identified by numerical designations like R-134a, R-410A, R-32, and others. Each refrigerant has unique properties, including:

- Molecular Weight: The weight of a single molecule of the refrigerant. This influences the density of the refrigerant in both its liquid and gaseous phases.

- Density: The mass per unit volume of the refrigerant. This changes with temperature and pressure, meaning the weight of a specific volume of refrigerant can vary depending on its state.

- Pressure-Temperature Relationship: Refrigerants operate under specific pressure-temperature relationships. Understanding this is vital for proper system operation and safe handling.

The Importance of Accurate Measurement in HVAC Systems

Precise measurement of refrigerant is critical for several reasons:

- Optimal System Performance: Overcharging or undercharging a system with refrigerant can significantly impact its efficiency and performance. Overcharging can lead to increased pressure, potentially damaging components, while undercharging reduces cooling capacity.

- System Longevity: Incorrect refrigerant charge contributes to premature wear and tear on components, shortening the lifespan of the entire system.

- Environmental Impact: Accurate refrigerant handling minimizes leaks, which is crucial for protecting the environment, as many refrigerants are potent greenhouse gases.

- Safety: Improper handling and inaccurate measurement can lead to dangerous situations, including exposure to harmful refrigerants and potential system malfunctions.

Methods for Measuring Refrigerant

Several methods are used to measure refrigerant charge in HVAC systems:

- Weight Scales: The most accurate method involves using a calibrated scale to measure the weight of the refrigerant added to the system. This allows for precise control over the charge.

- Liquid Level Indicators: Sight glasses or electronic indicators provide a visual representation of the liquid refrigerant level in the system. This method is less precise than weight measurement but provides a general assessment.

- Subcooling and Superheat Measurements: These measurements, taken with specialized tools, help determine the refrigerant charge indirectly by assessing the refrigerant's thermodynamic properties.

Common Misconceptions about Freon and Refrigerant Weight

Several misconceptions surround Freon and refrigerant weight:

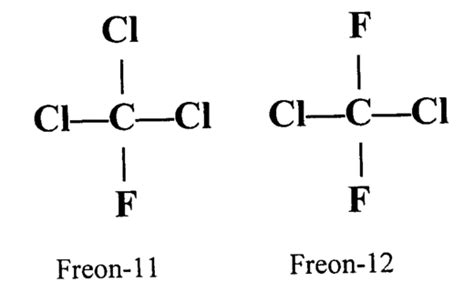

- "Freon" as a Universal Term: It's crucial to remember that "Freon" is an outdated trademark. Modern refrigerants have specific designations like R-134a, R-410A, etc., each with its own properties.

- Assuming Constant Density: Refrigerant density isn't constant; it varies with temperature and pressure. Therefore, simple volume-based measurements are unreliable.

- Ignoring Safety Precautions: Handling refrigerants requires adhering to strict safety protocols to prevent leaks, exposure, and potential injuries.

Safety Precautions when Handling Refrigerants

Working with refrigerants demands strict adherence to safety procedures:

- Proper Ventilation: Always work in a well-ventilated area to minimize the risk of inhaling refrigerant vapors.

- Personal Protective Equipment (PPE): Use appropriate PPE, including safety glasses, gloves, and respirators, to protect against exposure to refrigerants.

- Leak Detection: Regularly check for leaks using leak detection equipment. Promptly address any leaks to prevent environmental damage and safety hazards.

- Refrigerant Recovery and Recycling: Follow proper procedures for recovering and recycling used refrigerants to minimize environmental impact. Improper disposal is illegal and harmful.

- Trained Professionals: HVAC work involving refrigerant handling should ideally be performed by trained and certified technicians.

Beyond Ounces and Pounds: Understanding Refrigerant Charge Calculations

Calculating the required refrigerant charge for an HVAC system is a complex process involving several factors:

- System Capacity: The cooling capacity of the system directly impacts the required refrigerant charge.

- Refrigerant Type: Different refrigerants have different properties, influencing the charge calculation.

- System Design: The specific design of the HVAC system, including piping length, component sizes, and other factors, affects the refrigerant charge calculation.

- Manufacturer Specifications: Always refer to the manufacturer's specifications for the optimal refrigerant charge for a specific system model.

The Importance of Accurate Refrigerant Charge for Efficiency

An accurate refrigerant charge is essential for optimal system efficiency. An undercharged system will struggle to achieve the desired cooling capacity, leading to higher energy consumption and decreased comfort. Conversely, an overcharged system can lead to increased pressure, potential component damage, and reduced efficiency.

Environmental Considerations and Refrigerant Selection

The selection of refrigerants involves careful consideration of their environmental impact. Modern refrigerants are designed to minimize their global warming potential (GWP) and ozone depletion potential (ODP). Choosing environmentally friendly refrigerants is crucial for responsible HVAC practices.

Conclusion: Precision and Safety in Refrigerant Handling

While the basic conversion of 16 ounces to a pound remains constant, the complexities of working with refrigerants extend far beyond this simple calculation. Understanding refrigerant properties, employing precise measurement techniques, and adhering to stringent safety protocols are vital for ensuring efficient, safe, and environmentally responsible operation of HVAC systems. Remember to always consult the manufacturer’s specifications and seek the assistance of qualified technicians when handling refrigerants. Accurate refrigerant charging is not just about a simple conversion; it's about system performance, environmental protection, and safety.

Latest Posts

Latest Posts

-

3 4 Ounce Is How Many Tablespoons

Mar 21, 2025

-

What Year Would I Be Born If I Was 17

Mar 21, 2025

-

What Is Longer A Kilometer Or A Mile

Mar 21, 2025

-

How Much Does A Full 15 Lb Propane Tank Weigh

Mar 21, 2025

-

Did Chester Wear A Brace On Gunsmoke

Mar 21, 2025

Related Post

Thank you for visiting our website which covers about How Many Ounces In A Pound Of Freon . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.