How Much Is 1 4 Of An Inch

Arias News

Mar 31, 2025 · 6 min read

Table of Contents

How Much is 1/4 of an Inch? A Comprehensive Guide

Understanding fractions of an inch is crucial in various fields, from woodworking and engineering to sewing and cooking. While seemingly simple, the precise measurement of 1/4 of an inch can be surprisingly nuanced, depending on the context and the tools used. This comprehensive guide will delve into the intricacies of measuring 1/4 inch, exploring different methods, tools, and applications.

What is 1/4 of an Inch?

1/4 of an inch represents one-quarter of an inch, meaning it's one part out of four equal parts that make up a whole inch. It's a common fraction used in imperial measurements, a system still prevalent in many parts of the world. Understanding this fraction is essential for accurate measurements and precise work.

Converting 1/4 Inch to Decimal

For those more comfortable working with decimals, 1/4 inch is equivalent to 0.25 inches. This decimal representation is often useful when using digital measuring tools or calculators.

Measuring 1/4 Inch: Tools and Techniques

Several tools can accurately measure 1/4 of an inch. The best choice depends on the application and required precision.

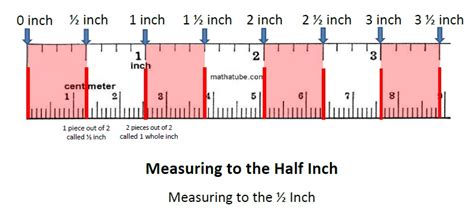

1. Standard Ruler

A standard ruler with inch markings is the most readily available tool. However, accurately measuring 1/4 inch using a standard ruler requires careful observation. Look for the markings that divide each inch into four equal parts. Each of these marks represents 1/4 of an inch.

- Limitations: Standard rulers can have limitations in precision, especially with worn-down markings or if your eyesight isn't perfect.

2. Metal Ruler or Steel Rule

Metal rulers, especially those made of stainless steel, often provide more durable and precise markings than wooden or plastic rulers. The etched markings are clearer and less prone to wear and tear. This makes them ideal for tasks requiring high accuracy.

- Advantages: Durability, clearer markings, better precision.

- Considerations: Metal rulers can be more expensive than plastic rulers.

3. Tape Measure

Tape measures are versatile tools for measuring larger objects or distances. Many tape measures have markings indicating 1/4 inch increments. However, the accuracy of a tape measure can vary depending on its quality and how well it's maintained.

- Advantages: Flexibility, suitable for measuring larger objects.

- Limitations: Accuracy can be lower compared to rulers, especially for small measurements.

4. Digital Caliper

For the highest degree of precision, a digital caliper is an excellent choice. Digital calipers provide precise readings to hundredths or even thousandths of an inch. They are frequently used in engineering, machining, and other applications demanding extremely precise measurements.

- Advantages: High accuracy, digital readout eliminates reading errors.

- Considerations: Higher cost compared to other methods.

5. Vernier Caliper

Similar to digital calipers, vernier calipers are known for their precision. Instead of a digital display, they use a vernier scale to allow for highly accurate readings. Vernier calipers offer excellent precision but require more skill to use properly.

- Advantages: High precision, no batteries required.

- Considerations: Requires training to accurately read the scale.

Applications of 1/4 Inch Measurements

The 1/4 inch measurement finds applications across a vast range of fields.

1. Woodworking and Carpentry

In woodworking, accuracy is paramount. 1/4 inch measurements are frequently used in determining the width of boards, spacing between components, and the depth of cuts. A slight error in a 1/4 inch measurement can significantly impact the final product. Precise measurements are crucial for ensuring joints fit snugly and the overall project maintains its integrity.

2. Sewing and Quilting

In sewing and quilting, a 1/4 inch seam allowance is a standard practice. This consistent seam allowance ensures that projects fit together properly and creates a professional finish. Accurately measuring 1/4 inch is vital for maintaining consistent seam allowances throughout a project. Inaccurate measurements can lead to poorly fitting garments or quilts.

3. Metalworking and Machining

Precision is paramount in metalworking and machining. 1/4 inch measurements are commonly used in determining the dimensions of components, the depth of cuts, and the spacing between parts. In these precision-oriented fields, using the right tools, like digital calipers or vernier calipers, is essential. A slight error can result in parts that don't fit correctly or even malfunction.

4. Plumbing and Construction

While less precise than in machining, 1/4 inch measurements still have importance in plumbing and construction. For example, the diameter of pipes or the spacing of fixtures might utilize 1/4 inch increments. Though the tolerance may be higher, understanding the measurement remains important for proper functionality.

5. Automotive Repair

In automotive repair, 1/4 inch measurements can be used in various contexts, such as adjusting components, checking clearances, and verifying the dimensions of parts. While tolerances are generally more flexible than in manufacturing, accurate measurements are vital for the safety and functionality of the vehicle.

6. Electronics

In electronics, precise measurements are crucial for the assembly and function of circuits. While often working with smaller units, 1/4 inch can still play a role in layout, spacing, and overall dimensions of components or circuit boards.

Troubleshooting Measurement Issues

Even with the right tools, issues can arise during the measurement process.

1. Parallax Error

Parallax error occurs when the observer's eye is not positioned directly above the measurement mark. This can lead to inaccurate readings. To avoid parallax error, always position your eye directly above the measurement mark.

2. Worn Ruler Markings

Over time, ruler markings can become worn or faded, making it difficult to accurately read measurements. Using a new or well-maintained ruler helps minimize this issue.

3. Incorrect Tool Usage

Using the wrong tool for the task can lead to inaccurate measurements. Always choose the tool that provides the appropriate level of precision for the task at hand. A standard ruler is sufficient for some applications, but others demand the precision of digital calipers.

4. Environmental Factors

Extreme temperatures or humidity can affect the accuracy of some measuring tools. Ensure the measuring environment is stable to minimize errors caused by environmental factors.

Conclusion

Understanding how much 1/4 of an inch is and how to measure it accurately is vital across numerous fields. From the intricate work of a machinist to the everyday tasks of a home handyman, mastering this simple fraction is key to achieving precise and reliable results. By choosing the correct tools and employing proper techniques, you can ensure accuracy and confidence in your measurements, leading to improved results in whatever project you undertake. Remember to always account for potential sources of error and select the most suitable tool for the required level of precision.

Latest Posts

Latest Posts

-

Born In 1958 How Old Are You

Apr 02, 2025

-

How Old Are You If You Was Born In 1977

Apr 02, 2025

-

If I M 5 11 At 14 How Tall Will I Be

Apr 02, 2025

-

What Is 3 4 Of 1 4

Apr 02, 2025

-

Alicia Did Not Select An Available City Pair Flight

Apr 02, 2025

Related Post

Thank you for visiting our website which covers about How Much Is 1 4 Of An Inch . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.