How Thick Is 20 Mil In Inches

Arias News

Mar 18, 2025 · 4 min read

Table of Contents

How Thick Is 20 Mil in Inches? A Comprehensive Guide to Thickness Conversions

Understanding different units of measurement is crucial in various fields, from manufacturing and construction to crafting and design. One common point of confusion revolves around the conversion of mils to inches, particularly when dealing with materials like plastic sheeting, films, and coatings. This comprehensive guide delves deep into the question: how thick is 20 mil in inches? We'll explore the conversion process, provide practical examples, and discuss the importance of accurate thickness measurements.

Understanding Mils and Inches

Before diving into the conversion, let's establish a clear understanding of the units involved:

- Inches: A widely used unit of length in the imperial system, equivalent to 1/12 of a foot.

- Mils: A unit of length representing one-thousandth of an inch (1/1000 inch). It's often used to express the thickness of thin materials.

Therefore, the core relationship between mils and inches is: 1 inch = 1000 mils. This simple equation is the cornerstone of all our conversions.

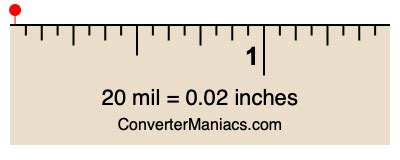

Converting 20 Mils to Inches: The Calculation

The conversion of 20 mils to inches is straightforward, thanks to the established relationship between the two units. We can use the following formula:

Inches = Mils / 1000

Substituting 20 mils into the formula:

Inches = 20 mils / 1000 = 0.02 inches

Therefore, 20 mils is equal to 0.02 inches.

Practical Applications and Examples

Understanding the thickness of materials expressed in mils is vital in numerous applications. Let's look at some real-world examples:

1. Plastic Sheeting and Film

Plastic sheeting and film are commonly specified in mils. A 20-mil plastic sheet, measuring 0.02 inches thick, would be suitable for certain applications, but not others. Its suitability depends on the intended use:

- Lightweight applications: 20-mil plastic sheeting might be sufficient for covering smaller items or as a lightweight protective layer.

- Heavy-duty applications: For applications requiring more durability and impact resistance, a thicker sheet would be necessary.

2. Coatings and Finishes

Coatings, paints, and other finishes are often measured in mils to express their thickness. A 20-mil coating would provide substantial protection, compared to thinner coatings, but the appropriate thickness ultimately depends on the material being coated and the desired level of protection.

3. Manufacturing and Engineering

Precision manufacturing and engineering rely heavily on accurate thickness measurements. In these contexts, converting mils to inches is critical for ensuring the proper fit and function of components. A deviation of even a few mils can affect the performance and reliability of a manufactured product.

Beyond the Basic Conversion: Exploring Related Thicknesses

While understanding how thick 20 mil is in inches is essential, it's also beneficial to expand our understanding to encompass related thicknesses:

- 10 mil (0.01 inch): Significantly thinner than 20 mil, often used for lightweight applications or where minimal thickness is crucial.

- 30 mil (0.03 inch): Thicker than 20 mil, offering greater strength and durability.

- 50 mil (0.05 inch): A substantial thickness, often found in heavy-duty applications requiring high impact resistance.

Understanding the relative thicknesses of these different mil measurements enables informed decision-making in various contexts.

Importance of Accurate Measurement and Conversion

Accuracy in measurement and conversion is paramount across many industries. Inaccurate conversions can lead to:

- Material waste: Incorrect estimations of material quantities can result in excess or insufficient material, leading to waste or project delays.

- Performance issues: Inaccurate measurements can affect the performance and functionality of products or components.

- Safety hazards: Incorrectly sized materials may compromise safety in critical applications.

Therefore, reliable conversion methods and precision measuring tools are essential for maintaining quality and efficiency.

Advanced Considerations: Material Properties and Applications

Beyond the simple conversion, the actual performance of a 20-mil material depends significantly on the material itself. The properties of the material, such as:

- Tensile strength: The material's ability to withstand stretching forces.

- Flexibility: How easily it bends or conforms to shapes.

- Impact resistance: Its ability to withstand impacts.

- Chemical resistance: Its resistance to various chemicals and solvents.

These properties, in addition to the thickness, determine the material’s suitability for a specific application. A 20-mil plastic sheet made from a high-strength polymer will have vastly different properties than a 20-mil sheet made from a less durable material.

Conclusion: Mastering Mil-to-Inch Conversions

Understanding the conversion of mils to inches, specifically knowing that 20 mils equals 0.02 inches, is crucial for numerous tasks. Accurate conversions prevent errors, ensure efficient resource management, and lead to superior results in a variety of applications. This guide provides a solid foundation for understanding thickness conversions and encourages the further exploration of material properties and their implications for specific applications. Remember to always double-check your measurements and conversions, especially in critical situations where precision is paramount. Mastering mil-to-inch conversions is a fundamental skill that significantly enhances proficiency in numerous fields.

Latest Posts

Latest Posts

-

How To Say Passion Fruit In Spanish

Mar 18, 2025

-

How Many Hours Are In 180 Minutes

Mar 18, 2025

-

How Many Acers Are In A Mile

Mar 18, 2025

-

Are Matthew Garber And Victor Garber Related

Mar 18, 2025

-

What Is Half Of 2 3 4

Mar 18, 2025

Related Post

Thank you for visiting our website which covers about How Thick Is 20 Mil In Inches . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.