Preservation Technique That Attempts To Remove Moisture Is

Arias News

Mar 28, 2025 · 6 min read

Table of Contents

Preservation Techniques That Attempt to Remove Moisture: A Deep Dive into Dehydration and Desiccation

Moisture is the enemy of food preservation. Microbial growth, enzymatic activity, and chemical reactions all thrive in the presence of water. Therefore, techniques that effectively remove moisture are crucial for extending the shelf life of various food products. This article delves into the world of dehydration and desiccation, exploring the principles, methods, and applications of these crucial preservation techniques.

Understanding the Principles: Dehydration vs. Desiccation

While often used interchangeably, dehydration and desiccation are distinct processes, albeit both aimed at moisture removal. The key difference lies in the extent of water removal and the methods employed.

Dehydration: Reducing Moisture Content for Extended Shelf Life

Dehydration is a process that reduces the moisture content of a food product to a level that inhibits microbial growth and enzymatic activity. It doesn't necessarily aim for complete dryness. The goal is to lower the water activity (a<sub>w</sub>) – a measure of the availability of water for microbial growth – to a level below that required for most spoilage organisms and pathogens. A typical a<sub>w</sub> for dehydrated foods is between 0.6 and 0.8.

Methods of Dehydration:

- Sun Drying: This ancient method uses solar energy to evaporate water from food. It's inexpensive but slow and susceptible to contamination.

- Air Drying: This involves circulating air over the food product to facilitate evaporation. The efficiency is increased by controlling temperature and humidity.

- Freeze Drying (Lyophilization): This sophisticated method involves freezing the food and then sublimating the ice directly into vapor under vacuum. This preserves texture and nutritional value better than other methods.

- Spray Drying: A liquid food is sprayed into a hot chamber, causing rapid evaporation. This is commonly used for powders and liquids.

- Vacuum Drying: This technique removes water under reduced pressure, lowering the boiling point of water and enabling lower temperatures. This helps retain volatile compounds and nutrients.

Desiccation: Extreme Moisture Removal Leading to Complete Dryness

Desiccation goes beyond dehydration. It's a process that aims for the almost complete removal of water, resulting in a very dry, brittle product. Desiccated foods have extremely low water activity (a<sub>w</sub> < 0.2), making them highly resistant to microbial spoilage. However, desiccation can sometimes compromise the texture and nutritional value of the food.

Methods of Desiccation:

Many of the dehydration methods described above can achieve a level of desiccation, depending on the parameters used. Prolonged sun drying, vacuum drying under extreme conditions, and specialized industrial drying processes can lead to desiccation.

Factors Influencing Moisture Removal Efficiency

Several factors significantly influence the effectiveness of dehydration and desiccation:

1. Food Composition:

The initial moisture content and composition of the food heavily impact the drying process. Foods high in sugar or salt require longer drying times due to their binding effects on water. The presence of fat can also slow down drying.

2. Temperature:

Higher temperatures generally accelerate the drying process, but excessive heat can damage the food's texture, color, and nutritional value. Optimizing temperature is crucial for balancing speed and quality.

3. Airflow:

Good airflow is essential for removing moisture from the food's surface, preventing condensation and promoting efficient evaporation. This is especially critical in air drying and sun drying.

4. Humidity:

Low humidity enhances the drying process, as it creates a larger vapor pressure gradient between the food and the surrounding air. High humidity hinders drying and can even lead to moisture reabsorption.

5. Surface Area:

A larger surface area of the food exposed to the drying process accelerates water removal. Slicing, dicing, or shredding food can significantly improve drying efficiency.

6. Vacuum:

The use of vacuum significantly lowers the boiling point of water, enabling drying at lower temperatures and preserving heat-sensitive components. This is a key feature of vacuum drying and freeze-drying.

Applications of Dehydration and Desiccation Across Various Food Sectors

Dehydration and desiccation techniques find widespread applications in preserving diverse food products:

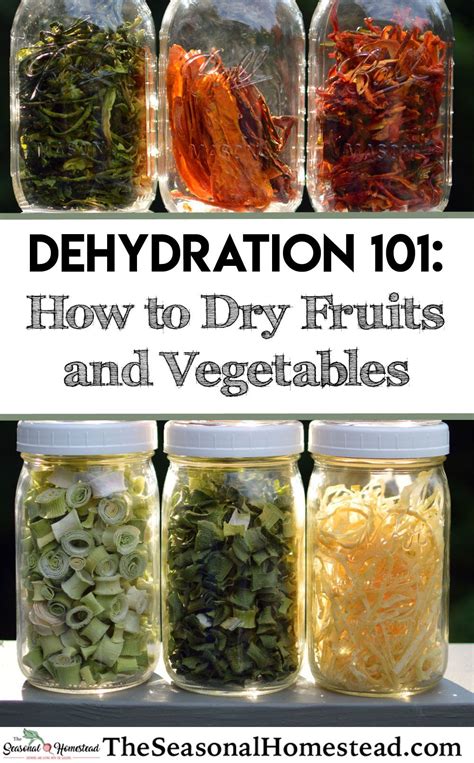

1. Fruits and Vegetables:

Dehydrated fruits and vegetables are popular snacks and ingredients, offering a convenient and long-lasting alternative to fresh produce. Examples include raisins, apricots, cranberries, and dehydrated onions, peppers, and carrots.

2. Meats and Poultry:

Dehydration and desiccation are used to produce jerky, a highly shelf-stable meat product. Similar techniques are also employed in the preservation of other meat and poultry items.

3. Dairy Products:

Milk powder is a key example of a dehydrated dairy product, enabling long-term storage and easy transportation.

4. Herbs and Spices:

Drying herbs and spices is a common practice to preserve their flavor and aroma for extended periods. This method enhances their shelf life significantly.

5. Grains and Legumes:

Drying grains and legumes after harvest is essential for long-term storage and preventing spoilage. This is a fundamental practice in agriculture and food production.

Advantages and Disadvantages of Dehydration and Desiccation

Advantages:

- Extended Shelf Life: The primary advantage is the significantly extended shelf life of food products, reducing spoilage and waste.

- Reduced Weight and Volume: Dehydration and desiccation dramatically reduce the weight and volume of food, making them easier to transport and store.

- Cost-Effective: While some methods (like freeze drying) are expensive, others like sun drying are remarkably cost-effective.

- Nutritional Value Retention (depending on method): Methods like freeze-drying preserve a higher proportion of nutrients compared to high-temperature methods.

- Convenience: Dehydrated foods are convenient to use, requiring only rehydration in many cases.

Disadvantages:

- Nutrient Loss (depending on method): Some vitamins and other nutrients can be lost during the drying process, particularly with high-temperature methods.

- Texture Changes: Dehydration can alter the texture of food, making it less appealing to some consumers.

- Rehydration Challenges: Proper rehydration techniques are crucial to restore the original texture and consistency of the food.

- Potential for Microbial Contamination: Improper drying methods can lead to microbial contamination if not done under strictly controlled conditions.

- Energy Consumption: Some methods, particularly freeze-drying, can have high energy demands.

Future Trends and Innovations in Dehydration and Desiccation

The field of dehydration and desiccation continues to evolve, driven by advancements in technology and a growing demand for efficient and sustainable food preservation methods. Some noteworthy trends include:

- Improved Drying Technologies: Research focuses on developing more efficient and energy-saving drying technologies, including advancements in microwave drying, pulsed electric field drying, and osmotic dehydration.

- Advanced Packaging: Improved packaging materials and technologies are crucial for maintaining the quality and preventing moisture reabsorption in dehydrated foods.

- Combination Preservation Techniques: Combining dehydration with other preservation methods, such as irradiation or high-pressure processing, can enhance food safety and extend shelf life even further.

- Focus on Quality and Nutrient Retention: Significant efforts are dedicated to optimizing drying parameters to minimize nutrient loss and maintain the sensory quality of the final product.

- Sustainability in Drying Processes: Emphasis is placed on developing sustainable and environmentally friendly drying methods that minimize energy consumption and waste.

Conclusion:

Dehydration and desiccation are invaluable preservation techniques that offer a wide range of applications in the food industry. By carefully controlling parameters like temperature, humidity, and airflow, and by choosing the appropriate method, it's possible to effectively remove moisture from food, significantly extending shelf life while retaining desirable qualities. Ongoing research and technological advancements continue to improve these methods, making them even more efficient, sustainable, and effective in the future. The continued exploration of these techniques is crucial for addressing the global challenges of food security and minimizing food waste.

Latest Posts

Latest Posts

-

35 Lbs Of Oil Is How Many Gallons

Mar 31, 2025

-

What Is One Percent Of 10 Billion

Mar 31, 2025

-

How Tall Is 35 Inches In Feet

Mar 31, 2025

-

How Much Is 6 Grams Of Sugar

Mar 31, 2025

-

What Did The Chef Say To The Hungry Watch

Mar 31, 2025

Related Post

Thank you for visiting our website which covers about Preservation Technique That Attempts To Remove Moisture Is . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.