What Is 2.8 Inches On A Ruler

Arias News

Mar 19, 2025 · 6 min read

Table of Contents

What is 2.8 Inches on a Ruler? A Comprehensive Guide

Understanding measurements is fundamental to numerous tasks, from crafting and construction to cooking and even everyday life. One common question that arises, particularly for those working with smaller scales, is "What is 2.8 inches on a ruler?" This seemingly simple query opens the door to a deeper understanding of measurement systems, ruler interpretation, and practical applications. This comprehensive guide will delve into the intricacies of measuring 2.8 inches, exploring different approaches and the significance of accuracy in various contexts.

Understanding the Inch and its Subdivisions

Before we pinpoint 2.8 inches on a ruler, let's establish a firm grasp of the inch itself. The inch is a unit of length in the imperial and U.S. customary measurement systems. It's defined as 1/12 of a foot, and 1/36 of a yard. Historically, the inch's definition has varied slightly across different regions and time periods, but modern standards have ensured uniformity.

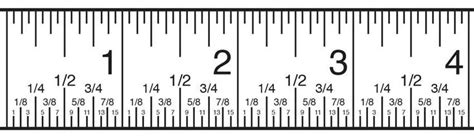

A standard ruler typically displays inches as marked lines, often with numbered markings representing whole inches (1 inch, 2 inches, 3 inches, and so on). However, accurately measuring 2.8 inches requires an understanding of the ruler's subdivisions. These subdivisions usually represent fractions of an inch, most commonly:

- Half inches (0.5 inches): These are usually marked as longer lines between whole inches.

- Quarter inches (0.25 inches): Represented by shorter lines between half-inch markings.

- Eighth inches (0.125 inches): Even shorter lines subdividing the quarter-inch segments.

- Sixteenth inches (0.0625 inches): Often the smallest subdivisions found on standard rulers.

- Thirty-second inches (0.03125 inches): Found on more precise rulers or measuring tools.

Some rulers even incorporate decimal markings (0.1 inch, 0.2 inch, etc.), offering a different system of subdivision. The level of precision available depends entirely on the ruler itself.

Locating 2.8 Inches: A Step-by-Step Guide

Measuring 2.8 inches on a standard ruler requires understanding that 2.8 inches is equal to 2 full inches and 8 tenths of an inch. This can be broken down further:

-

Identify the 2-inch mark: Locate the "2" on your ruler. This is your starting point.

-

Find the 0.5-inch (half-inch) mark: From the 2-inch mark, move to the first longer line after it. This represents 2.5 inches.

-

Locate the 0.25-inch (quarter-inch) marks: There are two quarter-inch marks between the 2.5-inch mark and the 3-inch mark. Each represents an additional 0.25 inches.

-

Reaching 2.8 inches: To get to 2.8 inches, you need to add another 0.3 inches to the 2.5-inch mark. Since 0.3 inches is three-tenths of an inch, you need to estimate the position between the 2.5-inch and 2.75-inch marks (which is halfway between the second and third quarter-inch mark). This estimated point will represent approximately 2.8 inches.

Important Note: The precision you can achieve depends greatly on the ruler's quality and the markings it provides. A ruler with smaller subdivisions (e.g., thirty-seconds of an inch) allows for more accurate measurements.

Precision and Accuracy in Measurement

When working with measurements like 2.8 inches, the concepts of precision and accuracy become crucial:

-

Precision: This refers to how close multiple measurements are to each other. Using a high-precision instrument will result in measurements that are very close together.

-

Accuracy: This describes how close a measurement is to the true value. A highly accurate measurement accurately reflects the actual length.

For many everyday tasks, a relatively low degree of precision is acceptable. However, in fields like engineering or manufacturing, extremely high accuracy and precision are paramount to ensure the quality and safety of products.

The quality of the ruler directly impacts both precision and accuracy. A worn or damaged ruler can lead to inaccurate measurements. Similarly, a ruler with imprecise markings may produce inconsistent results.

Applications of 2.8-Inch Measurements

While 2.8 inches might seem like a specific and uncommon measurement, it finds application in diverse fields:

-

Crafting and DIY: Creating small wooden pieces, precise fabric cuts, or model building can require accurate measurements in the tenths of an inch.

-

Electronics and Circuitry: In electronics, circuit boards and components often have precise dimensions, and 2.8 inches might be relevant to placement or spacing.

-

Jewelry Making: In jewelry design and creation, accuracy is critical. Precise measurements are essential for ensuring proper sizing and creating aesthetically pleasing pieces.

-

Medical and Scientific Fields: While less frequent, specific medical equipment or experimental setups might involve measurements down to the fraction of an inch.

-

Engineering and Construction: Though larger measurements dominate in construction, detailed plans and precision parts might utilize this level of specificity.

Beyond the Ruler: Other Measuring Tools

While rulers are convenient for many applications, they might not always be the best tool for measuring 2.8 inches, especially when high accuracy is required. Alternative tools include:

-

Calipers: Calipers provide significantly higher precision compared to rulers, especially for measuring smaller dimensions. They offer both inner and outer measuring capabilities.

-

Micrometers: Micrometers are capable of achieving exceptionally high levels of precision, measuring down to thousandths or even ten-thousandths of an inch. These are typically used in precision engineering and manufacturing.

-

Digital Measuring Tools: Electronic measuring tools, like digital calipers or laser distance meters, offer automated measurements with digital readouts, minimizing human error and improving accuracy.

Tips for Accurate Measurement

Regardless of the tool you choose, always follow these practices to ensure accurate measurement:

-

Ensure proper positioning: Keep the ruler or measuring tool flat and perpendicular to the object being measured. Avoid angling, which can distort the reading.

-

Start at the zero point: Always begin measuring from the zero mark on the ruler to avoid errors.

-

Use appropriate tools: Select a measuring tool suitable for the required precision. For instance, using a ruler to measure a tiny component will be much less accurate than using calipers.

-

Maintain your tools: Regularly check your ruler or other measuring tools for damage or wear. A worn-out tool will yield inaccurate results.

-

Repeat measurements: Take multiple measurements and average them to improve accuracy and identify potential errors.

Conclusion

Understanding how to accurately measure 2.8 inches on a ruler, or with other tools, is a fundamental skill with far-reaching applications. From basic crafting to complex engineering, precise measurement is the cornerstone of successful projects. By mastering the techniques and choosing the right tools, you can ensure accurate results, minimizing errors and achieving high-quality outcomes. Always remember to prioritize precision and accuracy for the most reliable results. The ability to confidently and accurately measure small distances will greatly benefit various aspects of your work and life.

Latest Posts

Latest Posts

-

How Long Is 75 Days In Months

Mar 19, 2025

-

1 Gallon Of Gas How Many Miles

Mar 19, 2025

-

How Many Ounces Is One Slice Of Cheese

Mar 19, 2025

-

How Many 1 8 Are In 1 2

Mar 19, 2025

-

How To Beat Level 9 On Bloxorz

Mar 19, 2025

Related Post

Thank you for visiting our website which covers about What Is 2.8 Inches On A Ruler . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.